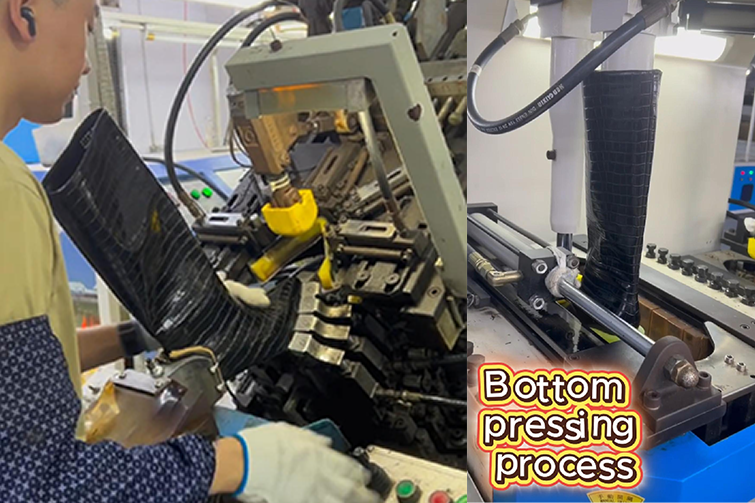

Guide to Assessing the Quality of Boot Bottom Pressing Process: Unveiling the Core Technology of High-Quality Women's Shoes

In the highly competitive women's shoe market, "high-end women's shoe customization" and "women's shoe OEM processing" have become the focus of many brand owners. As a leading factory with over 20 years of experience in women's shoe manufacturing, we have been providing professional OEM services to numerous brand owners, creating high-quality women's shoes that conform to the "2025 women's shoe fashion trends". The boot bottom pressing process is a crucial part that determines the quality of women's shoes. The quality of this process directly affects the durability, comfort, and appearance of the shoes. Today, we will provide you with a detailed analysis of how to assess the quality of the boot bottom pressing process and uncover the technical secrets behind high-quality women's shoes.

I. Precise Fit: Laying the Foundation for Quality

High-quality boot bottom pressing is first reflected in the perfect fit between the sole and the boot shaft. In the "women's shoe production process", professional bottom pressing technology requires that the joint between the sole and the boot shaft is tightly seamless, without any gaps, warping, or unevenness. Especially in areas with large curves such as the toe and heel, precise fitting is required to avoid water ingress, sand entry, or accelerated wear caused by poor fitting. In addition, the alignment of the sole edge and the boot shaft is also crucial. Both feet should be symmetrical, and the lines should be smooth and consistent, ensuring that each pair of boots has an exquisite appearance and meets the quality requirements of brand owners for "fashionable women's shoes".

II. Firm Connection: Ensuring Durability

1. Bonding Process: Firm and Traceless

For boots using the bonding process, when inspecting the quality of bottom pressing, you can gently bend the joint between the sole and the boot shaft to feel if it is firm and not loose. Under normal circumstances, high-quality bonding technology should make the sole and the boot shaft closely connected without any "loose bonding" phenomenon; when gently scraping the bonding edge with your finger, there should be no colloid overflow or peeling. As a professional "women's shoe OEM factory", we strictly control the bonding process to ensure that each pair of boots can withstand market tests.

2. Stitching Process: Fine and Regular

If boots are reinforced with stitching during bottom pressing, the quality of the stitching becomes the key to assessment. Carefully observe whether the stitching is even, flat, and whether the stitch spacing is consistent, and check for any missing stitches, skipped stitches, or loose thread ends. High-quality stitching should not only penetrate the sole and the boot shaft to ensure firmness but also control the depth to avoid piercing the shoe upper and affecting the appearance. Our technical team continuously researches and combines traditional craftsmanship with modern technology to create exquisite stitching that meets the standards of "high-quality women's shoes".

III. Stable Pressing: Enhancing the Wearing Experience

A pair of boots with excellent bottom pressing technology should show good stability when under pressure. You can press the middle and edges of the sole to feel if there is any significant deformation or looseness. With professional technology, the sole should be closely combined with the boot shaft, without any abnormal noise or displacement when bearing force. In addition, try to gently bend the shoe body to simulate the walking state and observe whether there is a cracking trend at the joint between the sole and the boot shaft, or whether there are wrinkles or bulges caused by uneven pressing, so as to judge whether the pressing strength meets the standard. We understand that "women's shoe comfort" is an important factor for consumers to choose products, and stable pressing technology is the core to enhance the wearing experience.

IV. Detail Polishing: Demonstrating Ingenuity

High-quality bottom pressing technology is often reflected in the pursuit of perfection in details. Check whether the pressing marks on the edge of the sole are even, and avoid situations where the marks are too deep or too shallow in some areas, because overly deep pressing marks may cause the sole to crack, while overly shallow marks will affect the firmness. At the same time, pay attention to the connection between the heel and the sole to see if there are additional reinforcement treatments, such as rivets or secondary pressing. These details are directly related to the durability of high-stress parts. In addition, if the sole is made of rubber or other materials, observe whether the edge after pressing is smooth without burrs to prevent excessive wear or scratching of clothes caused by the burrs. As a "women's shoe source factory", with more than 20 years of OEM experience, we strictly control every production process, especially the core processes such as boot bottom pressing, to ensure that we provide brand owners with high-quality and high-performance women's shoe products.

If you have any questions about the boot bottom pressing process, "women's shoe OEM services", or current women's shoe fashion trends, please feel free to contact us. We look forward to working with you to create more high-quality women's shoe products that meet market demands!